by Kai Yuan, PhD. QLF Senior Technical Advisor & Senior Scientist

Robotic milking systems are gaining popularity among dairy producers. There are several key nutritional factors to success with milking robots.

Excellent feed bunk management

Feed high quality forage in partially mixed ration (PMR). Ideally, forage in PMR should provide good digestible energy with moderate amount of starch. Feed bunk management is especially important in robotic milking systems, because cows need to receive adequate fiber to support a healthy rumen function. If cows consume excessive amounts of high-starch robot pellets without sufficient fiber intake from the bunk, subacute ruminal acidosis may occur. Consistent feed delivery and frequent feed pushups are required to have a good bunk management. Siewert et al. (2018. J. Dairy Sci. 101:8327-8334) showed that compared with manual feed push up, herds using automatic feed push up had over 10 lbs more milk per cow. After studying 36 robotic dairy farms in Midwest, Peiter et al., (2019. J. Dairy Sci. 102 Suppl. 1:223) reported that using an automatic manure scraper resulted in an increase of 320 lbs of milk/robot compared with manual scraping. These observations are likely due to more frequent and consistent task completion using automation, and less disruption to normal cow behavior and resting.

Robot feed quality and palatability

In order to get cows to visit milking stations, providing a high quality and palatable feed in the robots is crucial, because cows are motivated more by feeding than milking. Cows generally prefer pellets to meals, and they can consume pellets faster than meals in a given time. If the pellet quality is high, the speed of feeding can be as high as 0.8 to 1 lb/min. This is important because the box time of milking is limited, and some cows need to eat as quickly as they can to receive adequate amount of concentrate. Pellets that are prone to crumbling are not desirable. Cost of robot pellets is also a key consideration when making a feed choice. Some farms have had success using byproduct-based pellets that are high in digestible fiber instead of high starch. Previous research (Halachmi et al. 2006. J. Dairy Sci. 89:3241-3249) also showed that inclusion of soy hulls and corn gluten feed to replace starchy feeds did not negatively affect milking frequency or milk production. Depending on the ingredient price in your area, byproduct-based pellets can be more cost-effective aslong as pellet quality is maintained. Last but not least, managers of the robotic systems should make sure that robot feed is flowing and dispended accurately. Calibration the robot feed delivery system every few weeks is recommended.

Feeding more than one type of robot feed

A recent study (Peiter et al., 2019. J. Dairy Sci. 102 Suppl. 1:223) from University of Minnesota evaluated 36 robotic farms in Midwest, and found that using more than one type of robot feed was associated with greater milk production (Table 1).

Table 1: Feeding more than one type of robot feed was associated with higher milk yield.

| No. of robot feeds | milk/cow lbs | milk/robot lbs |

| 1 | 79.2 | 4627 |

| 2 | 80.5 | 4719 |

| 3 | 85.8 | 5034 |

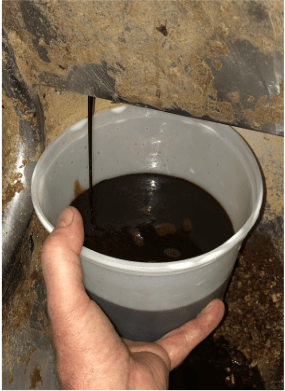

Enhancing the palatability of concentrate feed in robots through addition of flavoring substances has been shown to increase the number of visits to the milking systems. QLF molasses-based liquid product is an excellent type of feed used by many robotic producers to add palatability to robot feed and to entice cows to visit robots (Figure 1). Our commercial farm research in Michigan showed that delivering QLF feeds through robots increased milking frequency from 2.7 to 3 times per day. It also increased milk production and milk component yield per robot. Fetch cow numbers were dramatically reduced. Furthermore, the addition of QLF sugar products also increased rumination time per day by 30 min, suggesting improved cow comfort and rumen function. The benefits of molasses-based products in robotic systems are widely recognized by dairy producers and nutritionists. QLF currently has over 150 milking robot units across the Midwest implementing QLF liquid feeding systems in milking stations. The feeding rate of QLF supplement is usually around 3 lbs/d. The typical responses observed of feeding QLF through robots are reduced fetch cow numbers, increased rumination (25 to 30 min/d), increased milk production (3 to 4 lbs), and increased milk fat (0.2%) and protein (0.2%).

Figure 1: QLF liquid feeds delivered at robotic milking stations.

Feeding molasses-based products in robots may also allow for the reduction of pellet delivery. For farms using free flow traffic, the concentrate feeding amounts provided are often very high in order to attract cows to visit the milking systems. Some concentrate feeds are unconsumed or simply wasted. Research (Peiter et al., (2019. J. Dairy Sci. 102 Suppl. 1:M126) showed that residual feed and refusals per cow were negatively associated with milk production. The use of molasses-based products serves the purpose of enticing cows without the need to feed excessive amounts of concentrate feeds. This can help reduce feed costs and reduce the amount of starch consumed, minimizing the risk of ruminal acidosis. Just like the monitoring of dry robot feed, farm managers should routinely check and calibrate the liquid feed delivery system to make sure it is working properly. It is important to monitor the feed bowls to make sure most cows are cleaning feed up without excessive overfeeding.

More precise feeding regime based on level of production

In TMR feeding system, cows within the group are fed to an average production that inevitably causes some cows to receive more and others to receive fewer nutrients than they required. This inefficiency can be improved by using robotic milking systems. The amount of concentrate delivered through robots can be tailored to the needs of each cow depending on their production level and stage of lactation. In free flow traffic farms, fresh cows typically can start with 4 to 7 lbs of robot feed at calving and then increase 0.4 to 0.8 lbs/d until 7 to 14 days fresh. Continue to lead feed cows to maximize their potential of high production. Provide extra feed allowance for first lactation heifers as they have growth requirements in addition to lactation, and they also tend to visit robots less frequently than older cows. After cows reach mid-lactation, provide robot feed according to milk production, so that cows don’t get over-conditioned. In guided flow traffic farms, less robot feeds are needed, often 1 to 2.5 lbs per visit.

Number of cows per robot

The number of animals per robot is usually around 55 to 70 cows. Putting in more cows is not necessary better than fewer cows. To maximize the efficiency, the goal should be to maximize milk yield per cow. One area of focus is to optimize box time per cow, and it is desirable to have cows that can get attached fast and milked fast. Although theoretically reducing cow numbers per robot may increase the number of milkings from the remaining cows, thereby increasing their milk production, this is not the case all the time. Milkings per cow per day is not directly correlated with number of cows per robot. In other words, the average milking numbers per day is not as meaningful as having the right cows milk the right number of times per day according to their production level and stage of lactation.

Good cow health

Only healthy cows have the desire to voluntarily visit the systems to get milked. For example, prevalence of lameness is associated with lower milking frequency in robots. A study (King et al. 2016. J. Dairy Sci. 99:9069-9079) from University of Guelph reported 26% lameness prevalence in the robotic herds they evaluated. Lame cows are usually fetch cows, as they do not want to walk to robots to get milked. Type of floor and level of dietary starch are all linked to lameness. Feeding QLF supplements to replace some level of starch can help to reduce the risk. It is especially important to start with healthy prefresh and fresh cows, so that they can have high milk production and strong desire to visit robots to feed, which further drives production.

Summary

Robotic milking systems allow for feeding cows more precisely to their production and nutrient needs compared with traditional TMR system. Among the key nutritional factors for success with robotic milking systems, excellent feed bunk management and robot feed quality and palatability are especially important. Research showed that feeding more than one type of robot feed is associated with higher milk production. The addition of molasses-based QLF supplements in robots enhances the palatability and entices cows to visit robots more frequently. Currently we have over 150 robot units in the Midwest implementing our QLF feeding system. The typical responses of feeding QLF through robots are reduced fetch cow numbers, increased rumination (25 to 30 min/d), increased milk production (3 to 4 lbs), and increased milk fat (0.2%) and protein (0.2%). Other factors such as good cow health, low prevalence of lameness, number of cows per robots, and box time optimization all contribute to the efficiency and profitability of robotic milking systems.